ZINGER

Top Performance, Extraordinary Efficiency

We have eliminated processes in the desiccant dryer that utilize compressed air to only just one or none at all and reduced electricity consumption by heaters to an absolute minimum. All these without compromising dewpoint (no spikes). In fact, our dryers are capable of continuous -100°C pdp performance. We have set a new standard.

| A Type Compressed air used for cooling only. HEA Class Compressed air used for cooling only. Heater assisted by heat of compression. |

|

ZL Class Absolute Zero Loss. No air consumed. HEOC Class Absolute Zero Loss. No air consumed. Heater assisted by heat of compression. |

|

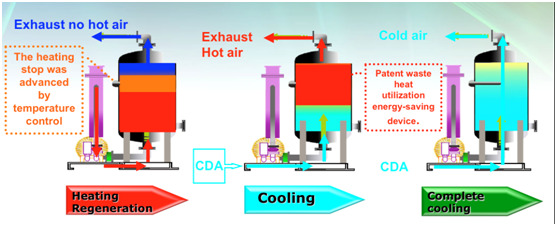

Waste Heat Recycling

Our Masterstroke in Energy Saving

Through dedicated R&D, we have engineered the unique Waste Heat Recycling process. A patented technology, we utilize instrumentation to exert greater control over desiccant regeneration, and keep heat use to an absolute minimum. Our heaters are turned off 20% earlier than typical dryers and the residual heat is put into use through integration of heating and cooling processes. This translates into 20% energy saving for you.

True Zero Loss (ZL & HEOC)

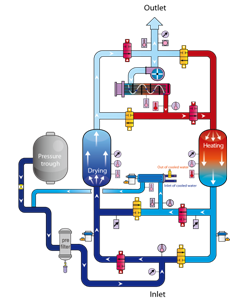

Process Diagrams for ZL

Typically, other zero-loss dryers lose compressed air when they depressurize characterized by the loud “boom” at the start of each regeneration cycle. This represents air loss equivalent to 6 or 7 times the volume of the desiccant tower. Our ZL and HEOC dryers regenerate under pressurized conditions. They do not depressurized. Another original energy saving feature from QYM.

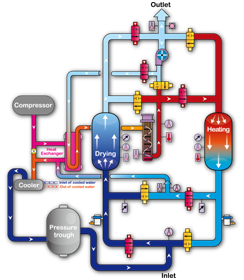

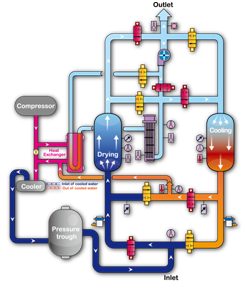

Process Diagrams for HEOC

Advanced Know-How

| OUR KNOW HOW | BENEFIT |

Adsorption Downstream Countercurrent adsorption & Co-current heating and cooling Desorption using heated ambient air Dry air is used for cooling process |

Increased Adsorption Efficiency of No re-adsorption of moisture during Prevents moisture contamination of Reduced consumption of dry air Eliminates Dewpoint Spike |